Machine Learning in the Prediction of Thermo-Fluid Behavior of Nanofluids

The complexity of the interactions between a base fluid and additive nanoparticles together with the instability of colloidal suspensions, the chaotic fluid dynamics, and the shape and size irregularity of engineered nanoparticles make accurate prediction and measurement of nanofluid thermo-fluid behavior a formidable task (Ma et al., 2021). Various influential factors and flow conditions nonlinearly affect the thermodynamics, heat transfer, fluid flow, and thermo-optical performance of nanofluids. A large amount of research data have been reported in the literature, yet some contradictory results exist. Nevertheless, machine learning techniques may be utilized as an alternative approach due to their ability to identify complex nonlinear patterns in data and make accurate forecasts.

Machine learning is an effective tool that can learn from data automatically, enabling the models to improve their prediction accuracy through learning experiences. Machine learning models trained on a vast amount of sample data can identify complex nonlinear relationships between input and output data with high precision. Traditional experimental and numerical research methods can be time-consuming and expensive. Conversely, machine learning approaches utilize existing data, reducing investigation time and minimizing the workload for humans. There are many algorithms that can be used to model data, most of which fall under three categories: supervised, unsupervised, and reinforcement learning. For example, multi-layer perceptron (MLP) artificial neural network (ANN) is a supervised learning algorithm. Other ANN algorithms include the radial basis function network and the adaptive neuro-fuzzy inference system (ANFIS). A machine learning algorithm can also be combined with genetic algorithm (GA), particle swarm optimization (PSO), and imperialist competitive algorithm (ICA) to further improve their prediction accuracy and computational efficiency.

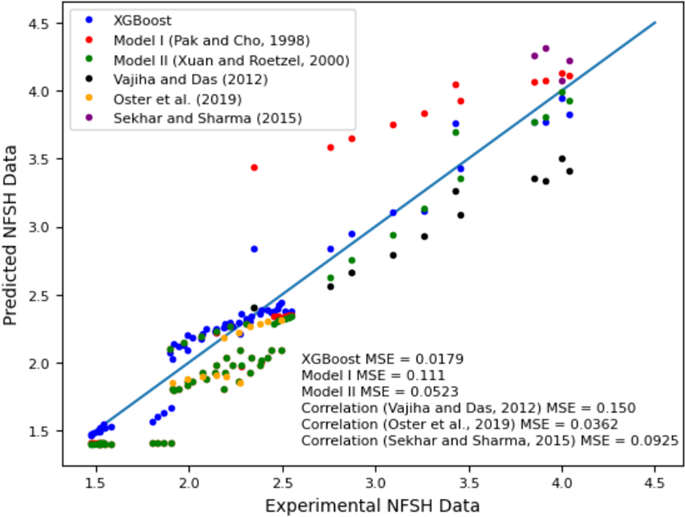

In a recent study, Oh and Guo (2024) found that the XGboost, an extreme gradient boosting decision tree based machine learning algorithm, exhibited an outstanding prediction performance with the lowest prediction mean square error (MSE) and the shortest execution time due to parallel computation capability in comparison with the MLP-ANN and the support vector regression (SVR) machine learning. It should be noted, however, that trained machine learning models strongly follow the specific patterns in the synthetic data. Thus, data quality is considered as a major concern in machine learning and a model should be trained on a reliable dataset and validated in predicting “unseen” data (i.e., data under similar conditions were not used for training). Fig. 1(a) compares the unseen data predictions of nanofluid specific heat (NFSH) derived from the XGboost model and other selected conventional correlations. The unseen data included Al2O3, CuO, MWCNT, Pd, or SiO2 nanoparticles in different base fluids. Models I (Pak and Cho, 1998) and II (Xuan and Roetzel, 2000) are two commonly adopted approximate methods. The correlation by Vajiha and Das (2012) was developed for predicting water based Al2O3 nanofluids, the correlation by Oster et al. (2019) was developed for estimating water based Al2O3, CuO, SiO2, or TiO2 nanofluids, and the correlation by Sekhar and Sharma (2015) was utilized in ionic liquid based MWCNT NFSH prediction. It was found that the Oster correlation gives a lower MSE of 0.0362 as it incorporates the effect of nanoparticle diameter, but it is still larger than the XGboost model which has the lowest MSE at 0.0179. If the XGboost model were trained with additional experimental data covering some “unseen” conditions, its prediction accuracy would have been improved substantially, as shown in Fig. 1(b), where the predicted data are dispersed narrowly around the diagonal line and the MSE is reduced by one order of magnitude.

![Improvement of XGboost with expanded training data. [Copied from Oh and Guo, Heat Transf. Res., 2024]](/content/10364/fig1b.png)

Figure 1. (a) Comparing the XGboost with approximate models and specific correlations in the prediction of unseen data; and (b) improvement of XGboost with expanded training data. [Copied from Oh and Guo, Heat Transf. Res., 2024]

REFERENCES

Ma, T., Guo, Z., Lin, M., and Wang, Q. (2021) Recent trends on nanofluid heat transfer machine learning research applied to renewable energy, Renew. Sustain. Energy Rev., vol. 138, Article ID 110494.

Oh, Y., and Guo, Z. (2024) Applicability of machine learning techniques in predicting specific heat capacity of complex nanofluids, Heat Transf. Res., vol. 55(3): 39–60.

Oster, K., Hardacre, C., Jacquemin, J., Ribeiro, A.P.C., and Elsinawi, A. (2019) Ionic liquid-based nanofluids (ionanofluids) for thermal applications: an experimental thermophysical characterization, Pure Appl. Chem., vol. 91(8): 1309–1340.

Pak, B.C. and Cho, Y.I. (1998) Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles, Exp. Heat Transf., vol. 11(2): 151–170.

Sekhar, Y.R. and Sharma, K.V. (2015) Study of viscosity and specific heat capacity characteristics of water-based Al2O3 nanofluids at low particle concentrations, J. Exp. Nanosci., vol. 10(2): 86–102.

Vajjha, R.S. and Das, D.K. (2012) A review and analysis on influence of temperature and concentration of nanofluids on thermophysical properties, heat transfer and pumping power, Int. J. Heat Mass Transf., vol. 55(15-16): 4063–4078.

Xuan, Y. and Roetzel, W. (2000) Conceptions for Heat Transfer Correlations of Nanofluids, Int. J. Heat Mass Transf., vol. 43(19): 3701–3707.

Использованная литература

- Ma, T., Guo, Z., Lin, M., and Wang, Q. (2021) Recent trends on nanofluid heat transfer machine learning research applied to renewable energy, Renew. Sustain. Energy Rev., vol. 138, Article ID 110494.

- Oh, Y., and Guo, Z. (2024) Applicability of machine learning techniques in predicting specific heat capacity of complex nanofluids, Heat Transf. Res., vol. 55(3): 39–60.

- Oster, K., Hardacre, C., Jacquemin, J., Ribeiro, A.P.C., and Elsinawi, A. (2019) Ionic liquid-based nanofluids (ionanofluids) for thermal applications: an experimental thermophysical characterization, Pure Appl. Chem., vol. 91(8): 1309–1340.

- Pak, B.C. and Cho, Y.I. (1998) Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles, Exp. Heat Transf., vol. 11(2): 151–170.

- Sekhar, Y.R. and Sharma, K.V. (2015) Study of viscosity and specific heat capacity characteristics of water-based Al2O3 nanofluids at low particle concentrations, J. Exp. Nanosci., vol. 10(2): 86–102.

- Vajjha, R.S. and Das, D.K. (2012) A review and analysis on influence of temperature and concentration of nanofluids on thermophysical properties, heat transfer and pumping power, Int. J. Heat Mass Transf., vol. 55(15-16): 4063–4078.

- Xuan, Y. and Roetzel, W. (2000) Conceptions for Heat Transfer Correlations of Nanofluids, Int. J. Heat Mass Transf., vol. 43(19): 3701–3707.